Technologies

Technologies

Minimized Out-of-Plane Motion

Microscopy and Digital Image Correlation are key to measuring strains on small length scales. When a sample moves out of plane under optical microscopes, the loss of focus is catastrophic for capturing the image. In an SEM, it causes false DIC strains. Psylotech’s load frames minimize out-of-plane motion in three ways: 1/complete symmetry around the loading plane, 2/high tolerance machining of all reference surfaces, 3/minimized number of moving parts.

High Resolution Load Cells

Psylotech’s high-res. load technology enables multi-scale force measurement, without the need to swap out & realign different sensors for different tests. These sensors offer a number of advantages over strain-gauged alternatives:

100x higher resolution enables a 100N load cell to perform like a 2N strain gauge sensor High safety factor because the 3x safety factor is based on the 100N full scale Alignment is quick and easy: the fixed cross-head, sensing element, and T-slot grip interface are precision wire EDM’ed from a single block High bending rigidity, which is critical for horizontally mounted load frames under high optical microscope magnification High resonance frequency for the low force, window scale Built on an AC excited capacitive bridge, high-res. load cells have 400mV/V sensitivity, compared to 2mV/V. More signal combined with similar signal to noise ratio means 50x higher resolution compared to strain gauge load cells.

The sensors offer better than 16 bit resolution. Low level signals are therefore conditioned along two parallel paths: 1/the Full Scale and 2/a smaller range, zoomed-in Window. The Window can be shifted anywhere within the Full Scale range. While absolute accuracy is based on the full scale, the Window provides accurate measurements of the change in load within its range.

To reduce thermal drift, Psylotech monitors the temperature of the sensor and the conditioning electronics, as well as the thermal gradient across the load cell body. An on-board accelerometer is also available for dynamic testing.

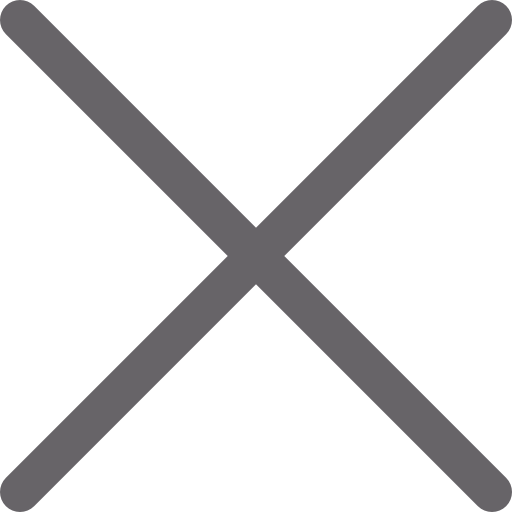

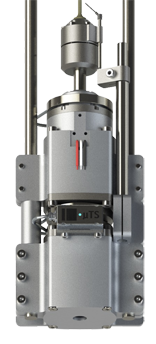

Fast, Direct Drive Ballscrew Actuators

Psylotech’s direct drive ballscrew actuators implement only two moving parts, reducing out-of-plane motion. The nut rotates and the screw translates. There are no gears or pulleys, eliminating stray forces that would otherwise twist the frame, causing micron scale out-of-plane motion. As an added benefit, the direct servo motor also provides substantial speed.

These servos implement a 26 bit, multi-turn encoder. For the 1mm lead of the 1.6kN standard system, this translates to 15 picometer resolution. Clearly, picometer control is not actually possible, but it does enable nanometer level motion.

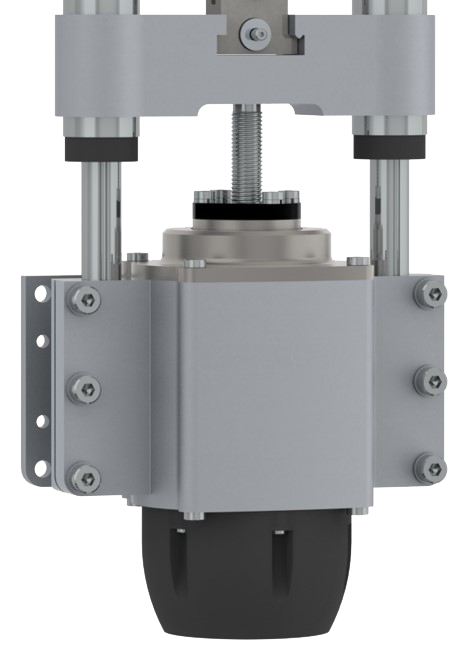

Local Displacement Sensor

For improved closed loop control on the nanometer scale, Psylotech applies its high resolution sensor technology to a local displacement sensor. Two LVDTs are positioned on opposite corners of the loading line, compensating nano scale pitch, yaw, & roll of the moving crosshead. The resulting measurement is on axis with the sample, rather than measuring the side of the crosshead far from the sample.

The dual LVDT setup circumvents viscoelastic grease and Herzian contact effects in the ballscrew. It also does not measure thermal expansion from the support posts. Furthermore, the LVDT cores are connected via sliding Invar extension rods, minimizing thermal effects.

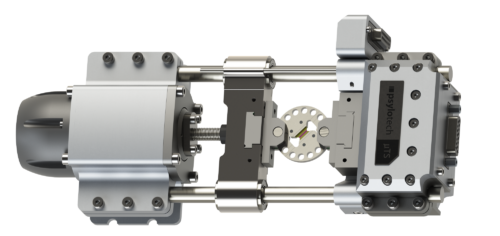

Torsion Actuator

Psylotech has developed a compact torsion actuator, built around zero-backlash strain wave gearing. The challenge with this technology is a constant velocity on the input causes a sinusoidally varying speed on the output. Leveraging nested control loops, the position loop is closed on a secondary encoder on the output shaft.

Psylotest Control Software

In keeping with Psylotech’s design philosophy to give experimentalists complete control over their experiments, our systems are controlled with a National Instruments LabVIEW based program. This code can be modified to meet individual specific needs.

Hardware Controllers

Psylotech applies industrial automation servo drives and controllers to the mechanical testing lab. These technologies have evolved over decades and are deployed in the 100’s of thousands annually. Such hyper-mature motion control technologies enable extremely versatile and sophisticated motion control.